HOP and the Railroad Industry

Build Your Railroad's Reliability Safety Sustainability Employees

With Us!

Introduction

The railroad industry is a vital part of transportation infrastructure, moving goods and people across the world. However, the industry is not without its challenges, including the risk of accidents and incidents that can have serious consequences. In this white paper, we will explore how Human and Organizational Performance (HOP) could benefit the railroad industry by enhancing safety, efficiency, resilience, and reliability. We will also examine what leading experts in the field have to say about the potential benefits of HOP in the railroad industry.

"HOP isn't about just managing human error; it's about understanding the human performance and improving systems to prevent that error from occurring in the first place."

- Tony Muschara

An aerial view of the Norfolk Southern freight train derailment in East Palestine, Ohio captured on Feb. 5, 2023. (Source: NTSB)

What is Human and Organizational Performance (HOP)?

HOP is a framework that seeks to enhance safety, efficiency, and resilience by examining how work is done and how people interact with the systems around them. HOP recognizes that humans are fallible and that errors are inevitable, but organizations can reduce the frequency and severity of errors by improving the way they manage their work systems and their people. HOP focuses on three key principles: systems thinking, risk management, and human performance.

How HOP Could Benefit the Railroad Industry:

The railroad industry faces numerous challenges in maintaining safety, efficiency, resilience and reliability in its operations. By adopting HOP principles and practices, the railroad industry could benefit in several ways, including:

HOP emphasizes understanding work environments and systems, proactive risk management, and fostering a learning culture. Implementing HOP helps railroads better understand human error and its causes, including local and organizational factors that contribute to error propagation. This approach identifies systemic issues and develops strategies to reduce the likelihood and impact of human errors.

Safety is crucial in the railroad industry due to the handling of hazardous materials in a dynamic worker environment. Adopting a systems thinking approach helps identify and address underlying systemic factors leading to accidents. With a focus on risk management, strategies can be developed to mitigate hazards and assess their effectiveness over time. The human performance approach enables the design of reliable and resilient work processes and systems that are less prone to errors and accidents.

The railroad industry is highly competitive, and efficiency is critical to maintaining a competitive edge. By adopting HOP principles and practices, the industry could streamline its processes, reduce waste, and improve productivity. By focusing on human performance which values worker input, the industry could design work processes and systems that are more intuitive, user-friendly, and less prone to errors and delays.

The railway industry operates in a complex and constantly evolving environment. Resilience is critical to adapting to changing circumstances. Resiliency enables organizations to bounce back from unexpected events and continue operations with minimal disruption. By adopting HOP principles and practices, the industry could build resilience in its workforce by providing workers with the necessary HOP tools, training, and support to respond to unexpected events and adapt to changing circumstances which increases reliability.

"HOP is not just about keeping people safe; it's about optimizing the performance of the entire organization, from the front-line worker to the CEO. It's about understanding how work is done and how people interact with the systems around them."

- Dr. Todd Conklin

Impact of Human Error on Rail Accidents

Human error has a significant impact on rail accidents, contributing to a considerable number of incidents worldwide. According to a study conducted by the Rail Safety and Standards Board (RSSB) in the UK, human factors, including human error, were identified as the cause or a contributory factor in approximately 70% of all rail accidents. The study found that errors made by individuals involved in the operation and maintenance of trains, signaling systems, and track infrastructure were responsible for a substantial portion of accidents.

Furthermore, a report by the Federal Railroad Administration (FRA) in the United States highlights the prevalence of human error in train accidents. According to the report, human factors were the leading cause of accidents in the U.S. railroad industry, accounting for more than one-third of all incidents. These errors encompass various factors, such as inattentiveness, distractions, fatigue, and inadequate training or experience. The report emphasizes the importance of addressing human factors through improved training, fatigue management, and the implementation of technology and automation systems to minimize the potential for human errors.

The causes of train derailments can be broadly categorized into two main factors: operational errors (human errors) and maintenance or upkeep abandonment. These categories highlight the preventable nature of most train accidents. Let's explore these causes in more detail.

Operational Errors

Human errors occur when train engineers or crew members are careless in their duties. Errors by the train engineer are primarily attributed to cell phone, drug, or alcohol use, or speeding while operating the train. Speeding is a significant contributing factor to train accidents. Errors by the crew include switching tracks improperly, disregarding safety precautions when pushing train cars, or leaving train cars in unsafe positions near other cars.

Maintenance Errors

Maintenance errors can pertain to the track or the train itself. Track defects are the second leading cause of train accidents. Issues such as broken or stretched rails, welds, or improper maintenance of ballast in areas prone to derailment, like bridges, can disrupt the alignment, gauge, and elevation of the train, leading to derailments. If the train track is not regularly and adequately maintained to detect possible defects, it can also result in catastrophic train wrecks.

While less common, signal and communication errors, as well as extreme weather conditions, can also contribute to train derailments.

"HOP is not about pointing fingers or blaming people for mistakes. It's about understanding how those mistakes happen and working to improve the system to prevent them from happening again."

- Dr. Erik Hollnagel

Interested in discovering how we can help your organization's reliability?

The railroad industry has experienced several high-profile incidents in recent years that could be leveraged to implement HOP principles and practices. Some examples include:

Norfolk Southern freight train derailment in East Palestine, Ohio

Lac-Mégantic Train Derailment

Amtrak Train Derailment in Philadelphia

NJ Transit commuter train Accident

"HOP recognizes that humans are fallible, and errors are inevitable. By adopting HOP principles and practices, the railroad industry can reduce the frequency and severity of errors by improving the way they manage their work systems and their people."

- Dr. Sidney Dekker

Challenges in the Application of HOP in the Railroad Industry:

Despite the potential benefits of HOP in the railroad industry, there are also some challenges in its implementation. One challenge is the highly regulated nature of the industry, which may limit the flexibility of organizations to adopt new approaches and practices. Additionally, there may be resistance to change among employees and stakeholders, which can hinder the adoption of HOP. Despite this, many organizations have overcome these challenges with a proven approach that includes; Leadership and HOP training, change management, enhanced organizational communications and a planned, dynamic, and strategic approach.

Conclusion

The railroad industry is a critical part of transportation infrastructure and faces numerous challenges in maintaining safety, efficiency, and resilience in its operations. By adopting HOP principles and practices, the industry could enhance safety, improve efficiency, and build resilience in its workforce which results in enhanced reliability. HOP could provide a holistic approach to addressing the complex interplay of human and organizational factors in the railroad industry, ultimately leading to a safer and more efficient industry. As Dr. Todd Conklin stated, "HOP is not a silver bullet, but it is a way to make work safer and better for everyone involved." The potential benefits of HOP in the railroad industry are significant and worth considering for organizations looking to improve their operations.

“HOP offers a valuable approach for enhancing safety, efficiency, and resilience within the railroad industry. This methodology focuses on understanding the interplay between people, processes, and technology. By embracing HOP principles and practices, railroads can cultivate a robust safety culture that equips employees with the necessary HOP tools, training, and support to effectively navigate unexpected events and challenges.”

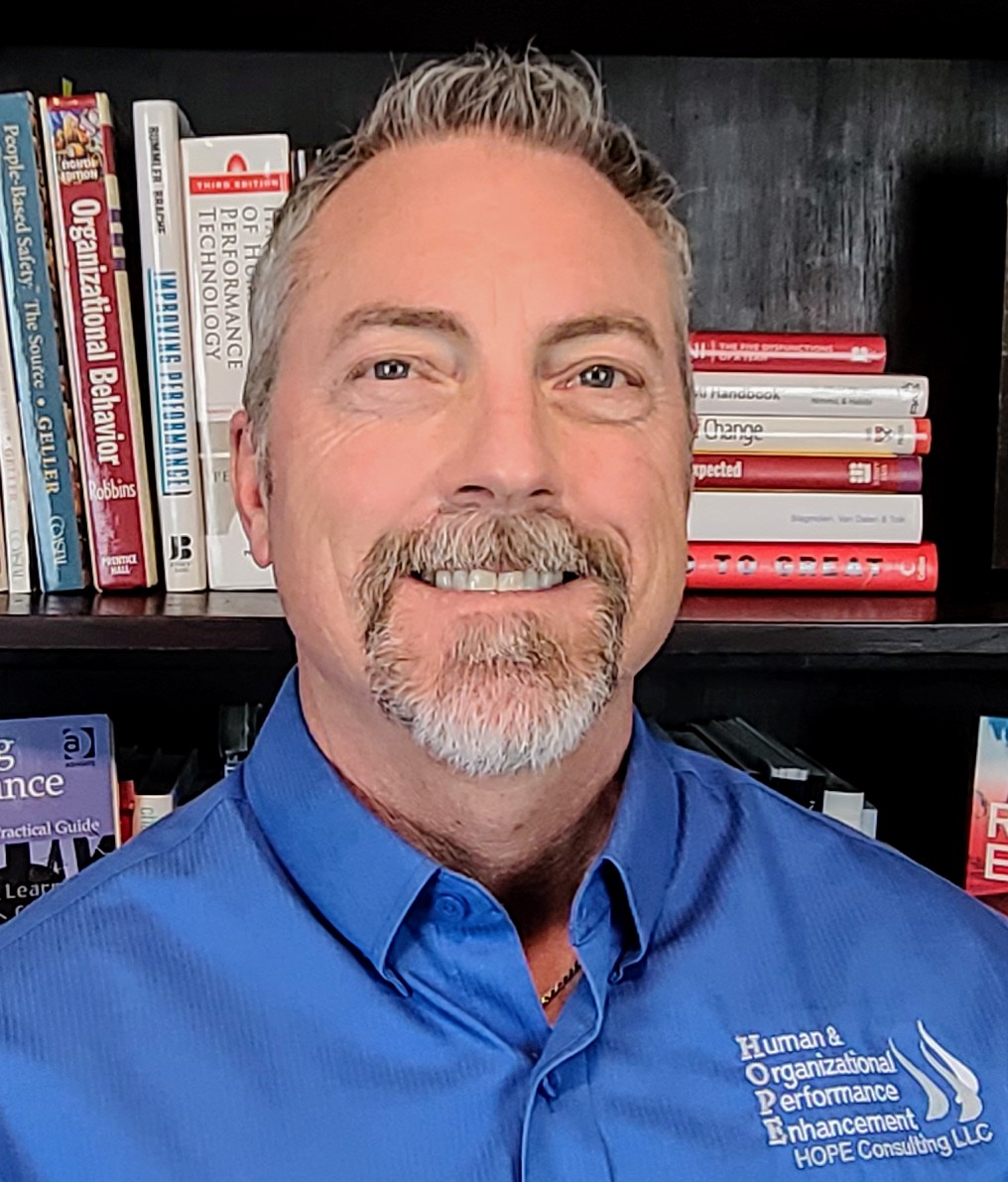

– Ron Farris

Ronald (Ron) Farris is a recognized expert in the field of Human and Organizational Performance (HOP) and High Reliability Operations (HRO) and the co-author of the book Critical Steps: Managing What Must Go Right in High-Risk Operations. With over 40 years of experience in high-reliability industries, Ron has worked with a variety of high-risk industries from around the world to improve safety, efficiency, and resilience by adopting HOP and HRO principles and practices.

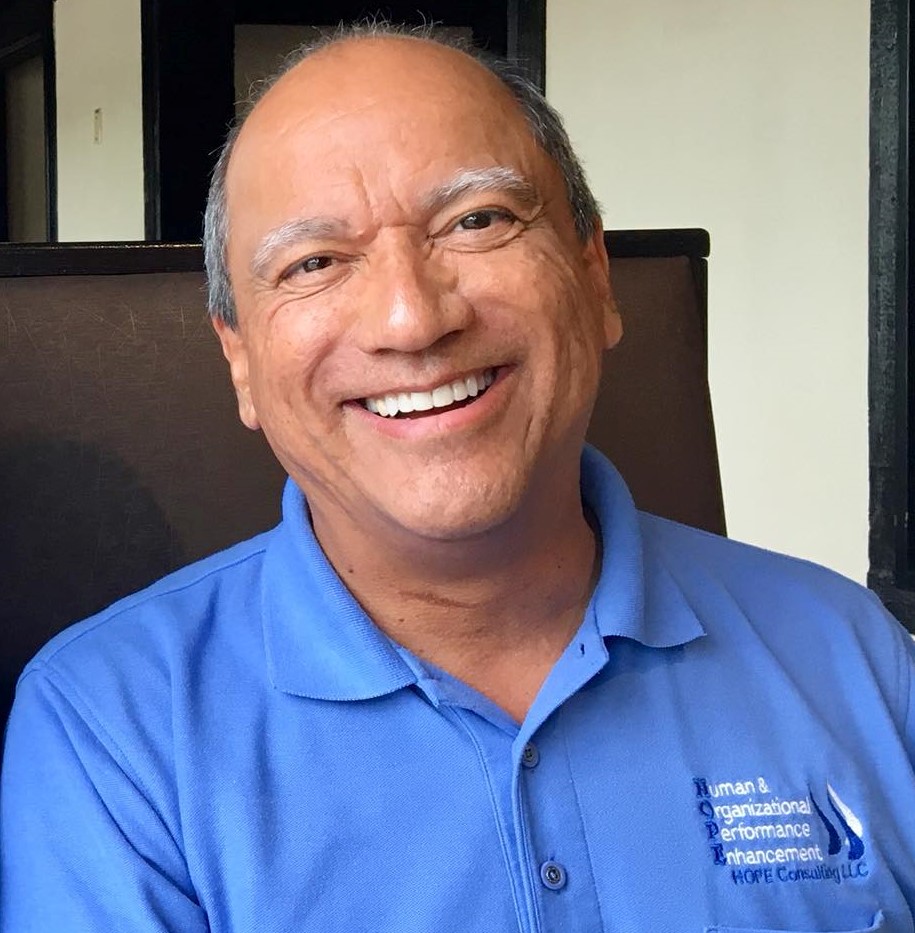

Rey Gonzalez is a recognized expert in the field of Human and Organizational Performance (HOP) and High Reliability Operations (HRO) and the author of the book Coaching to Enhance Performance: How Successful Leaders Create Sustainability Differently. With over 40 years of experience in high-reliability industries, Rey has worked with a variety of high-risk industries to improve safety, efficiency, resilience, and reliability by adopting HOP and HRO principles and practices.

T. Muschara, R. Farris, J. Marinus. (2022) Critical Steps: Managing What Must Go Right. CRC Press. https://www.criticalstep.com/

T. Muschara (2017) Risk-Based Thinking: Managing the Uncertainty of Human Error in Operations. Routledge. https://www.riskbasedthinking.com/

Conklin, T. (2018). Pre-Accident Investigations: An Introduction to Organizational Safety. Routledge.

Hollnagel, E. (2014). Safety-I and Safety-II: The Past and Future of Safety Management. Ashgate Publishing, Ltd.

Dekker, S. (2014). The Field Guide to Understanding Human Error. Ashgate Publishing, Ltd.

Leveson, N. G. (2011). Engineering a Safer World: Systems Thinking Applied to Safety. MIT Press.

Lac-Mégantic rail disaster. Retrieved from https://www.nytimes.com/2023/02/24/world/americas/canada-train- derailment.html#:~:text=At%20about%201%3A15%20a.m.,incinerated%20most%20of%20its%20downt own.

Amtrak train derailment. Retrieved from https://casetext.com/case/in-re-amtrak-train-derailment-in- philadelphia

New Jersey Transit train crash. Retrieved from https://en.wikipedia.org/wiki/2016_Hoboken_train_crash#:~:text=On%20September%2029%2C%202016%2C%20an,and%20114%20others%20were%20injured.

Federal Railroad Administration (FRA). (2021). Railroad Accidents: Human Factors. Retrieved from https://railroads.dot.gov/program-areas/human-factors/human-factors-overview

Norfolk Southern freight train derailment in East Palestine, Ohio. Retrieved from https://www.ntsb.gov/news/press-releases/Pages/NR20230214.aspx

Most Common Causes of Train Derailments. Kwartler Manus, LLC. (n.d.). Retrieved from https://www.krlawgroup.com/most-common-causes-of-train-derailments/

Interested in discovering how we can help your organization's reliability?

Train derailment 7/17/2023 in Whitemarsh Township. Photographer: Monica Herndon

Discover how we can solve your employee challenges.

Assessment

Training

Data Management

Sustainability

Premium Services

What We Do

High Reliability Training was formed because of lack of quality online and video-based curriculum in the areas of Human and Organizational Performance (HOP) and High Reliability Operations (HRO).